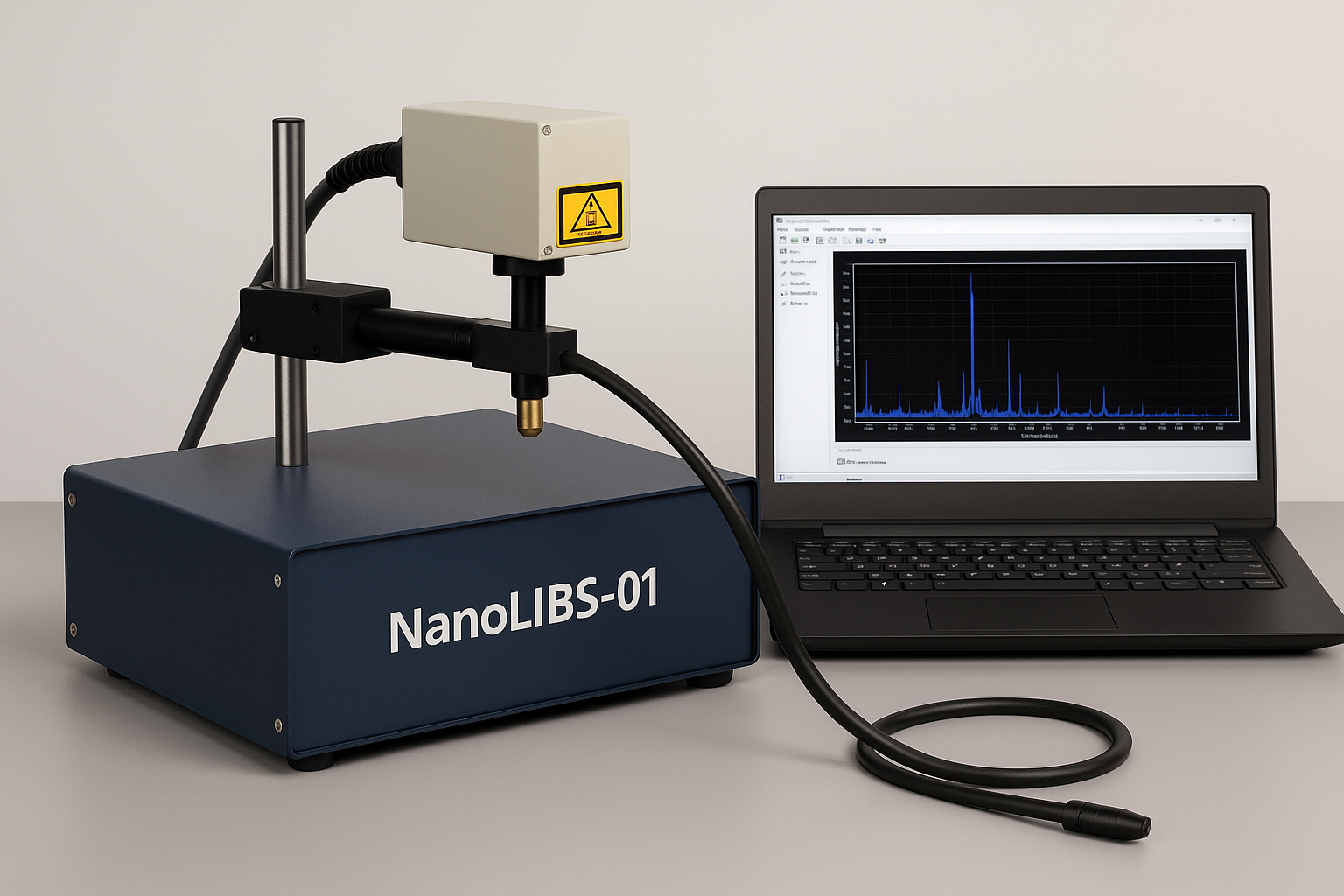

NanoLIBS: Industrial LIBS Spectroscopy System

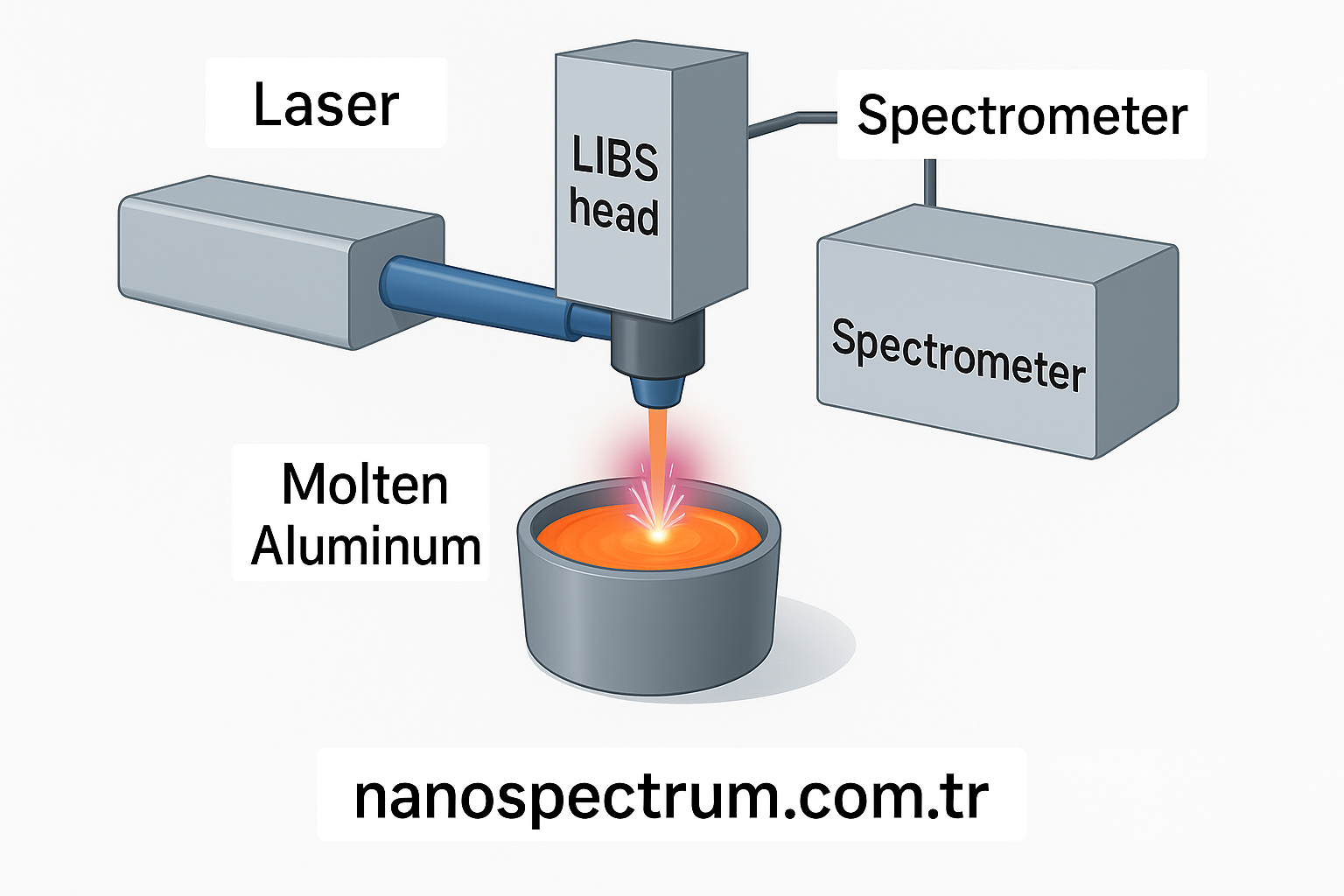

NanoLIBS is a high-performance, industrial-grade Laser-Induced Breakdown Spectroscopy (LIBS) system developed by Nanospectrum for real-time, contactless elemental analysis in production environments.

Designed for seamless integration into manufacturing lines, NanoLIBS enables rapid identification of materials, detection of contaminants, and validation of alloy compositions — all without the need for sample preparation.

Key Features

- Real-time elemental analysis with sub-second response

- Non-destructive and contactless operation

- Compatible with metals, alloys, ceramics, and coatings

- Operates in atmospheric or vacuum environments

- AI-powered spectral matching and classification algorithms

- Compact, modular design for easy industrial integration

Industrial Applications

- Aluminum and steel alloy verification in foundries

- In-line quality control for metal production

- Contaminant detection on electronic and automotive components

- Coating thickness and composition verification

- Mining and raw material analysis (e.g., Cu, Zn, Fe, Al ores)

Technical Specifications

| Laser Source | Nd:YAG, 1064 nm, 50-100 mJ per pulse |

|---|---|

| Spectrometer | High-resolution CCD array, 200–800 nm range |

| Detection Time | < 1 second per measurement |

| Atmospheric Conditions | Ambient, inert gas, or vacuum compatible |

| Control Interface | Touchscreen panel + PC-based software + remote API |

| Software | AI-enhanced peak identification, trend logging, spectral database integration |

Why Choose NanoLIBS?

NanoLIBS provides a compact, scalable, and high-throughput alternative to traditional XRF or OES systems. Its ability to deliver fast, precise, and real-time feedback makes it an essential tool for modern production lines where material integrity and traceability are critical.